SOURCE: Global Water Intel

https://www.globalwaterintel.com

2019 has seen Electro Scan’s in-pipe leak detection alternative to CCTV move into the mainstream as US utilities look to secure their wastewater networks. Has the California firm found a niche that others have missed?

Two deals signed with utilities in Florida and Missouri in July 2019 further propelled Electro Scan’s electrode-based leak detection solution into the US municipal market as traditional pipe inspection methods fall short of tackling sewer network infiltration and leaks.

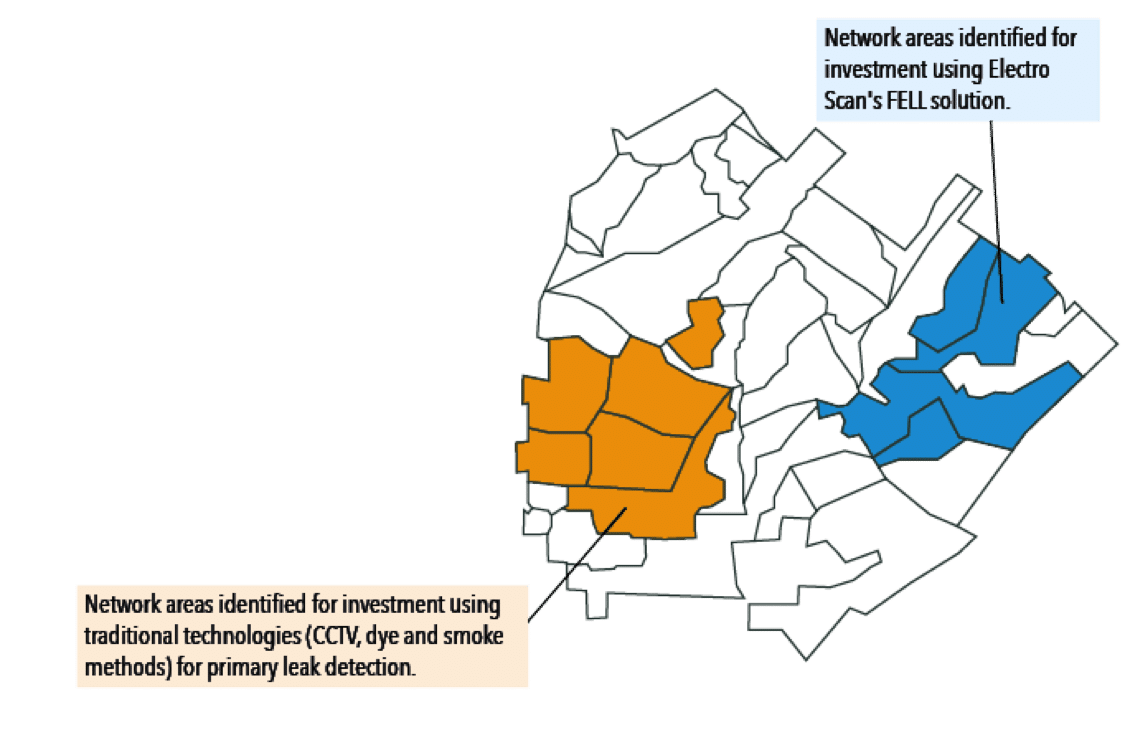

“Municipalities are spending billions of dollars dealing with the effects of sewer faults,” Mike App, Electro Scan’s vice president told GWI. “Many, such as the City of Kansas City, Missouri, initially deployed CCTV or dye and smoke-based methods for primary leak detection. Those methods don’t provide the intelligence they need to make really targeted investment decisions so now they’re looking to us for something different.”

Despite securing its first commercial deployments back in 2016 in Japan, the UAE and Germany, Electro Scan has struggled for traction in its domestic market. This has changed in recent months, and the firm now has active projects with more than 20 municipalities across the United States, including major projects in San Antonio, Texas, and now Tampa, Florida, and Kansas City. “These are tent pole municipalities,” App explained. “Having them bring us on board – in the case of Kansas City, with the expressed target of reducing their spending by $1 billion – is huge for us.”

The City of Kansas City is currently subject to an EPA consent decree to reduce pollutant infiltration into separate sewer systems and minimize both the frequency and volume of CSO events. Andy Shively, the city’s special assistant city manager, recognizes there is still work to be done, with the utility looking for ways to improve its compliance. “Traditional methods could identify defects but needed visual inspection to determine their intensity. Electro Scan’s technology allows us to pinpoint defect locations and measure sources of infiltration in gallons per minute, eliminating the need for follow-up inspections.” Following on from a 2017 pilot, Electro Scan’s technology will be used to survey 35km of Kansas City’s wastewater network as part of the city’s $4.5 billion 25-year ‘Smart Sewer’ program, providing a technology-as-a-service licensing agreement while a national contractor completes the field work.

Electro Scan’s Focused Electrode Leak Location (FELL) solution involves passing a probe through a customer’s network, connected to a deployment support vehicle by a cable around 1000m in length. The probe emits a 60-milliamp current into the water, producing a one kilohertz signal distinct from that emitted by anything else in the ground, minimizing the chances of false positives. “If there’s a breach in the pipe, the electricity escapes with the water,” App explained. “It completes the circuit through a grounding rod attached to the support vehicle. We then measure the intensity and duration of the signal and score it relative to all the other faults we find, prioritizing points of interest. Other methods can’t do that. CCTV can’t tell if cracks propagate through the pipe and misses around 80% of the faults we find.”

An in-house developed, cloud-based analytics system then processes the results of the scan in real-time, reporting fault location and intensity, and generating automated maintenance guidance for operators. Currently used only for wastewater, the solution is already optimized for use in potable water networks and once certified for deployment – with global approval expected in 2020 – Electro Scan will pursue that market.

THE MORE YOU KNOW

The FELL solution has the ability to simultaneously describe leak location to within 1cm as well as intensity in litres per second, helping users target maintenance investment with increased volumes of accurate data. In the case shown here, a US utility projected 80% leak reduction with $12m investment guided by conventional technology. In practice, the project yielded <30% improvement. A FELL survey suggested their money would have been better spent elsewhere.

Electro Scan has been developing its system since 2011 when company founder, Chuck Hansen, took up the rights to the underlying technology. “We added cloud-based analytics the following year, and in 2013, the EPA started studying it,” App explained. “We began being included in consent decrees as a secondary verified methodology to determine leaks in pipes in 2014.”

To date, Electro Scan’s customers have been almost exclusively municipal, with 70% of the firm’s business coming in the form of service deployments, with Electro Scan’s technicians completing surveys and providing clients with network assessments to guide maintenance. The remaining 30% of business comes in the form of equipment sales.

App hopes recent contract successes will now see Electro Scan kick on. “In the first half of 2019, our solution identified almost 21,000 leaks with a combined loss potential of around 300,000m3 per day,” he told GWI. “With the projects in Kanas City and Tampa launching in July, this year is a water shed moment where FELL and Electro Scan achieved market acceptance. We can only grow from here.”

Global Water Intelligence

https://www.globalwaterintel.com