One of the state’s largest water utility is facing significant challenges with excessive inflow and infiltration (I/I) in its gravity collection system, consisting of over 1,500 miles. Precipitation events often result in immediate flow responses within the collection network, at times up to 3 times the average daily flow rates.

New Regulatory Considerations

The Florida Clean Waterways Act became law in 2020 requiring all Florida utilities to focus greater attention on sanitary sewer overflow (SSO) control and reduction. Strict new reporting requirements and fine structures mean that Florida water infrastructure managers will need to develop robust asset management programs to establish optimal collection system performance. Meanwhile, COVID-19 fiscal realities have caused stark choices to be made regarding capital spending priorities.

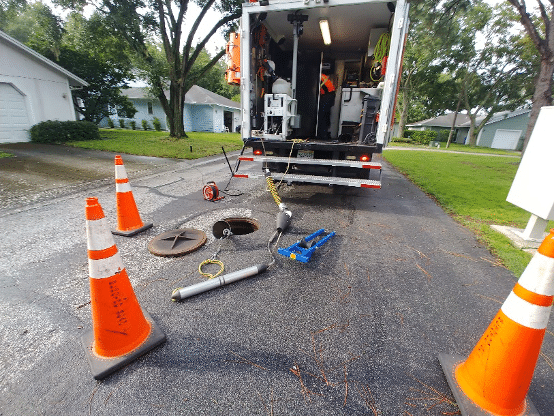

In the past this utility has relied heavily on closed-circuit television (CCTV) visual pipe inspection to set rehabilitation priorities, as well as verifying water tightness after new sewer liners were installed. Significant capital spending for both inspection and rehabilitation work has not seen an expected corresponding I/I reduction. A new inspection method was sought to identify and target I/I locations.

MEANINGFUL DATA GUIDES DECISION-MAKING

After completing nearly 25 miles of gravity pipe collection inspection work, results revealed:

- Only 25% of all pipes inspected contribute 76% of the potential I/I flow rate. Detailed reports showed engineering and collections staff where the problems were, and what steps were needed for the lowest cost rehabilitation strategy to avoid costly spending for pipes that do not contribute to I/I. Capital cost avoidance may exceed $2.5 million using FELL data.

- In a side-by-side comparison between CCTV and FELL results for 33,000 LF of the project, the PACP reports documented only 14 individual defects contributing to I/I, as compared to 1,227 defects located and quantified by FELL.

- Customer tap connections at the sewer main lines were carefully evaluated for water tightness. The CCTV inspection reports identified only 5 individual taps of 283 total, or 1.7%, as having defects contributing to I/I. By contrast, FELL’s machine-based and unbiased results documented 178 defective customer taps, or 63%, with specific leak measurements quantified for each tap. Thus, FELL data allow identifying leak rates at specific tap locations, allowing for targeted rehabilitation prioritization.

Based on results from two studies, this utility has adopted FELL inspection for its rehabilitation strategy development and will be retrofitting one of its in-house CCTV inspection trucks to add FELL inspection equipment in 2021 so that collections staff members can self-perform the work going forward.

Details of this study may be requested by contacting Electro Scan Inc.