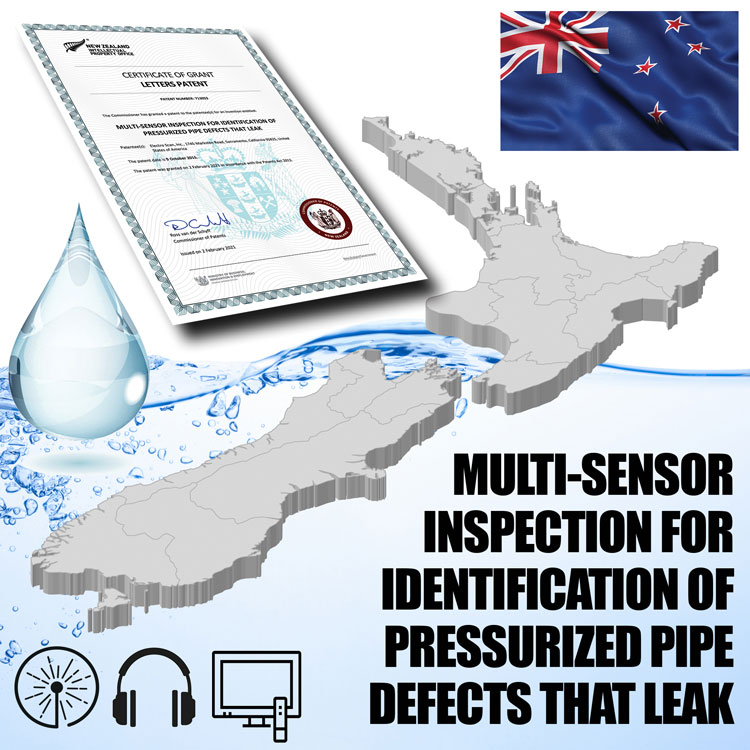

New Zealand Issues Patent for Multi-Sensor Machine-Intelligent Probe for Leak Detection. New Technology Doesn’t Require ‘Hearing’ Leaks and Has 1cm Accuracy.

SACRAMENTO, CALIFORNIA, USA, February 15, 2021 /EINPresswire.com/ — California-based cleantech leader, Electro Scan Inc., announced its 14th international patent for its groundbreaking multi-sensor technology that accurately locates & measures water leaks.

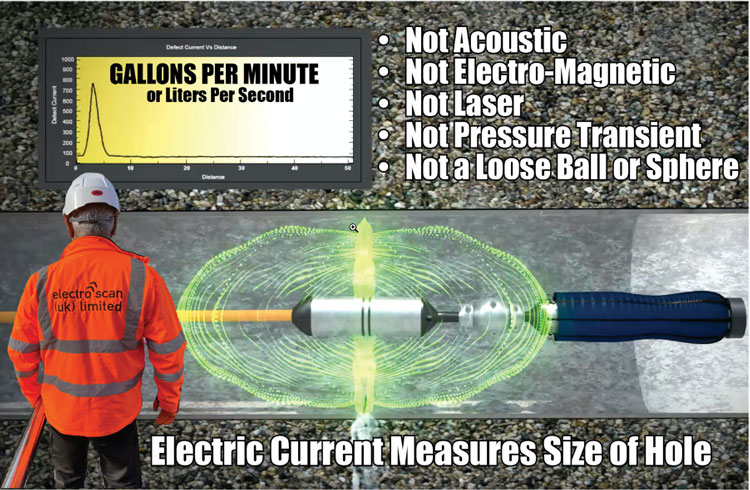

While traditional solutions ‘listen’ for a leak or rely on cameras to ‘see’ a leak, Electro Scan’s machine-intelligent probe automatically measures leaks by locating actual cracks & holes that go through the pipe wall, measuring the size of each opening using harmless low voltage electric current.

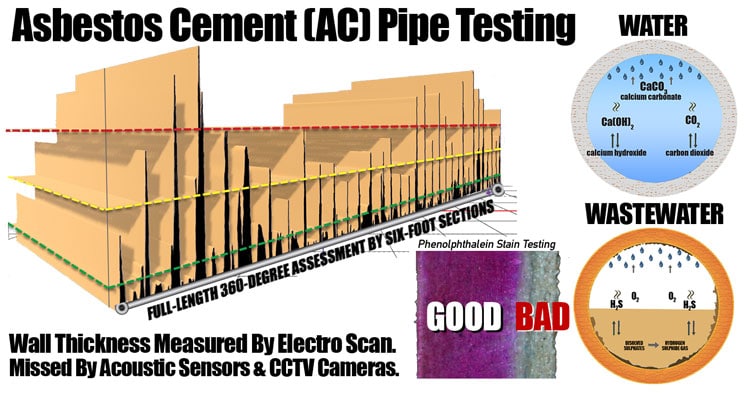

The Electro Scan technology also evaluates pipe wall thicknesses, particularly in Asbestos Cement (AC) pipes that tend to burst, collapse, or lead to catastrophic failure without warning.

The company’s award-winning cloud application reports leak locations in minutes – to the closest centimeter or 3/8th of an inch – and quantifies severity expressed in industry standard Gallons per Minute or Liters per Second.

Announcement of the new patent is timely, especially as New Zealand is in the midst of a water crisis where the Government recently created a new regulator, Taumara Arowai, proposing to take control of water from 67 councils to be reorganized into several publicly-owned regional water authorities.

Electro Scan’s Founder, Chuck Hansen, is no stranger to the New Zealand water industry, choosing to ground truth his patented leak detection solutions in Christchurch from 2012 to 2013.

But, Hansen’s work with the New Zealand water market began even earlier.

In 1999, Hansen won a competitive New Zealand water & sewer asset management tender, issued by the ASSOCIATION OF LOCAL GOVERNMENT ENGINEERS OF NEW ZEALAND (ALGENZ), later merged into INGENIUM, and then becoming the INSTITUTE OF PUBLIC WORKS ENGINEERING AUSTRALASIA (IPWEA).

“I knew that acoustic leak detection and CCTV data were not delivering the value needed to protect our water supplies and contain our effluent, and had to do something about it.”

— Chuck Hansen, Chairman & CEO, Electro Scan Inc.

As part of the tender, Hansen was required to build the world’s first asset accounting solution to track all underground pipes and fixtures, linked to his industry standard water and sewer asset management system. This allowed NZ Councils to capitalize all sewer & water assets, recognize depreciation, and track capital expenditures, by individual asset, sometimes representing 70-80% of a city’s total financial assets.

After 27-years in business and serving over 2,000 worldwide utility customers, Hansen sold his company in 2007 to international accounting & enterprise resource planning (ERP) supplier, INFOR Global, for US$100 million.

“Having worked in the water & sewer business for nearly 40 years, I knew that acoustic leak detection and CCTV data were not delivering the value needed to protect our water supplies and contain our effluent, and had to do something about it.” stated Hansen.

“While artificial intelligence (AI) and machine learning algorithms show real promise, applying these to legacy inspection tools like Acoustic & CCTV-based audio and video files, respectively, still do not pinpoint sources of water contamination or sewer seepage,” commented Hansen. “New technologies were needed.”

New Zealand’s summer has already seen a record number of towns issuing ‘boil water’ notices, including Naseby, Pateroa, Te Horo, Otematata, Duntroon, Tokarahi, Awamoko, Cannington, Motukaika, Featherston, Martinborough, Coromandel Town, and Mt Pleasant in Christchurch.

Worldwide, aging infrastructure has resulted in hundreds of millions of miles of underground water and sewer pipes with cracks and holes.

But the use of traditional acoustic listening sensors in pressurized water mains and long-time use of closed-circuit television cameras in gravity sewer pipes, have been unable to reliably locate or quantify leak locations or their size.

In water pipes, when pressure drops below acceptable levels, cracks and holes allow groundwater to seep back into potable systems. Some of that groundwater can carry harmful bacteria that can only be eliminated by boiling the water.

Because leak sounds occur as turbulence is created at a leak location when the inside and outside pressures are trying to equalize, if leaks are surrounded by groundwater, when contamination risks are highest, the ability to hear a leak is actually at its lowest, regardless of pipe material.

In sewer pipes, contractors have successfully fought to keep using CCTV cameras to approve pipes as watertight, despite the inability to tell if cracks go through a pipe wall or if pipe joints have hidden pathways through narrow bell & spigots that allow unseen sewage to seep out of a pipe.

In fact, most ratepayers are surprised to learn that most pipe acceptance standards allow new & rehabilitated pipes to leak; oftentimes allowing only ‘visual inspection’ to accept pipes assumed to have 50-year useful lives.

As a result, acoustic, data correlators, ground penetrating radar, lasers, LIDAR, satellite, and sonar, have been ineffective in locating or quantifying leaks.

Recent studies of Cured-In-Place Pipe (CIPP) – a more than $10 billion business, worldwide – have found leaks can be worse after CIPP, especially if liner bags have not been properly inflated or ‘cooked’ and customer service locations improperly cut.

Since the CIPP process temporarily closes customer tap openings for water and sewer delivered to homes and businesses, precision based rotating blades must cut through the newly lined pipe. If not exact in their cutting, original host pipes may be damaged causing large leaks to be unnoticed by CCTV cameras or simply unreported as most inspections are completed by the same company installing the CIPP.

The problem, years in the making, is only solved by new technologies like the company’s patented solutions that can deliver unambiguous, unbiased, and unprecedented data, minutes after surveys are completed.

A major field trial of the company’s sewer leak detection products were completed by Sydney Water Corporation in December 2019.

To coax reluctant New Zealand councils to fix their pipes, NZ ministers came up with an additional NZ$761 million to help replace leaky pipe networks and other deteriorating assets. Using legacy acoustic and camera-based technologies risk correct location and prioritization of pipes to be repaired.

In total, NZ councils have allocated NZ$17.2 billion for water infrastructure spending over the next decade and overall face a NZ$30-NZ$50 billion dollar infrastructure deficit.

Earlier this month, New Zealand’s Intellectual Property Office granted Patent Number 713053 for Electro Scan’s ‘MULTI-SENSOR INSPECTION FOR IDENTIFICATION OF PRESSURIZED PIPE DEFECTS THAT LEAK,’ filed in 2015.

Electro Scan’s new technology is a game-changer that is 80-100 times more effective than leaks found by listening (Acoustic sensors), seeing (cameras), and smelling (helium tracers & water sniffing dogs).

The technology is already included as part of the American Water Works Association (AWWA) Water Supply Standard, M77 Water Main Condition Assessment, and American Society for Testing and Materials (ASTM) F2550-13 (2018).

In January 2021, Electro Scan Inc. was selected ‘WATER LEAK DETECTION SOLUTION OF THE YEAR’ for 2021 by IoT Breakthrough.

The Company was also chosen winner of the November 2020 UK Water Dragons Competition sponsored by UK-based Future Water Association.

“Our team is delighted to expand our patent protection to New Zealand,” stated Hansen. “And we look forward to working with IPWEA and Water Services Association of Australia (WSAA) to upgrade their condition assessment standards to more accurately identify sources of water contamination and unintended sewage releases.”

Studies find that for every US$1 invested in safe water and sanitation it yields US$5-to-US$28 due to increased economic activity and reduced health care costs.

Today, it is estimated that 25-33% of Chinese do not have access to safe drinking water.

As governments look to stimulate their economies during the post-COVID-19 pandemic recovery, adoption of innovative technologies that allow communities to ‘Build Back Better’ and ‘Find Leaks Before Breaks’ are good first steps. Besides, studies find that every US$1 invested in safe water and sanitation yields US$5-to-US$28 due to increased economic activity and reduced health care costs.

Contact the company for international water loss projects and Non-Revenue Water assessments, including technology-as-a-service (TaaS) licensing opportunities and equipment purchasing.

ABOUT ELECTRO SCAN INC.

Electro Scan Inc., is a leading supplier of machine-intelligent pipeline assessment products and services for the water & wastewater pipeline market, developing proprietary pipe condition assessment equipment and delivering field services, and cloud-based applications that automatically locate, measure, and report leaks typically not found by legacy inspection methods. Follow Electro Scan Inc. on LinkedIn.

HASTAGS

#acoutics #acousticsensors #acp #ai #amp7 #artificialintelligence #asce #awwa #cipp #climatechange #conditionassessment #conductivity #deeplearning #drainage #drought #electromagnetic #fell #hdpe #infrastructure #innovyze #inspection #ipwea #leak #leakdetection #machinelearning #ml #nassco #pacp #pcat #pe #piperepair #plasticpipe #pressuretransient #pvc #resilient #resiliency #sewer #sewerai #swan #trenchless #utilities #vcp #wastewater #water #waterai #wsaa #wrc #wrcplc #worldbank #wsaa

Carissa Boudwin

Electro Scan Inc.

+1 916-779-0660

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn